AUTOMATE PRODUCTION WITH THE BENEFITS OF CNC MACHINE TOOLS

How a CNC Machine Tool Transforms Modern Manufacturing

In today's fast-paced manufacturing industry, CNC machine tools have revolutionized the way products are made. These advanced machines, equipped with computer numerical control (CNC) technology, offer precision and efficiency like never before. Understanding the Benefits of CNC Manufacturing helps explain why these systems have become essential across modern production environments. As a CNC machine tool distributor and supplier of top-of-the-line machinery, we understand the importance of reliable equipment in a competitive market.

CNC machines come in various forms, including mills, machining centers, lathes, and more, making them versatile tools for any machine shop. By partnering with reputable CNC machine tool distributors, businesses can access the latest CNC machinery and automation solutions to streamline their production processes and stay ahead of the curve.

Whether you're looking to upgrade your existing equipment or invest in new CNC machines, choosing the right CNC machining distributor can make all the difference in the success of your operations. Join us as we explore the world of CNC machine tools and discover how these innovative machines are shaping the future of manufacturing.

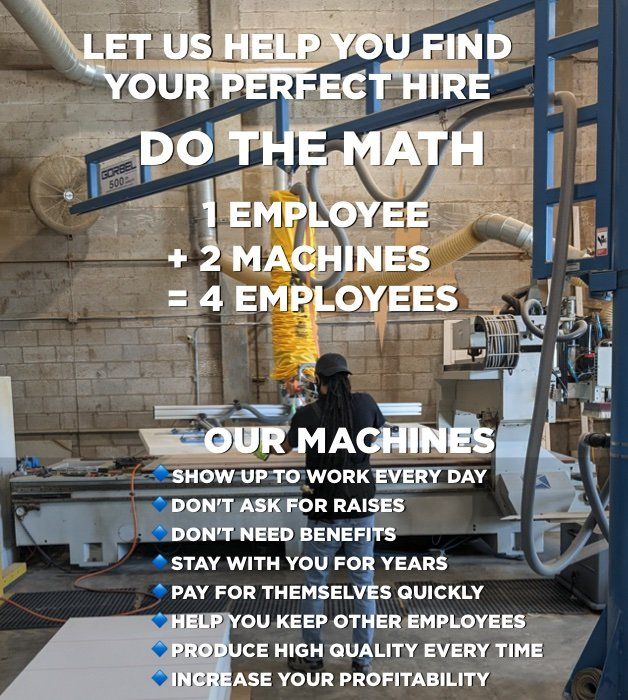

Frustrated by the "Great Resignation"?

Struggling to find the right people?

Worried they won't show up?

Concerned that you can't afford to pay what they want?

MAYBE IT'S TIME TO THINK DIFFERENTLY.

Florida Lumber Company Captured Huge Staff Savings With CNC Machines.

This Florida lumber company offers catalogs and custom doors. Their first piece of equipment was a pre-owned ANDI Stratos Pro CNC router, which they installed in 2009.

More recently, they added a vacuum lifter (shown above) which allowed one operator to load materials without help easily As the operator became familiar with the lifter, the company saw production steadily increase.

They soon realized the same operator could feed two machines.

What would have normally required four employees could be accomplished by just one employee.

Employee satisfaction increased, quality increased, and production increased while staffing needs decreased along with the variable costs for employee benefits, leading to greater profits.

Shop owners will continue to face staffing challenges for the foreseeable future.

Why Choose Us

We’re more than CNC machine distributors, we’re your long-term partners. From selecting the right equipment to ongoing tooling and programming support, we ensure your shop succeeds with the benefits of CNC. Our team has over 30 years of hands-on CNC machine tool experience across manufacturing sectors.

Frequently Asked Questions About CNC Machine Tools

What are the main benefits of CNC?

The main benefits of CNC involve producing accurate and repeatable parts with minimal manual adjustment. CNC machines help maintain consistent quality, especially during long runs or detailed projects. Automation allows work to continue with fewer interruptions while reducing the likelihood of human error. These systems also support better use of staff time, since operators can oversee several processes at once instead of focusing on a single manual task.

How does a CNC machine tool reduce staffing needs?

A CNC machine tool reduces staffing needs by automating tasks that would normally require multiple people. Because the machine controls movement, cutting paths, and material handling steps, a single operator can oversee several machines at the same time. This setup minimizes manual involvement while still maintaining output. It also helps shops continue production when staffing levels change, since operators can manage more work without requiring additional personnel for each machine.

How does a CNC machine tool reduce staffing needs?

A CNC machine tool reduces staffing needs by automating tasks that would normally require multiple people. Because the machine controls movement, cutting paths, and material handling steps, a single operator can oversee several machines at the same time. This setup minimizes manual involvement while still maintaining output. It also helps shops continue production when staffing levels change, since operators can manage more work without requiring additional personnel for each machine.

How do I choose a CNC machine tool distributor?

When choosing a CNC machine tool distributor, look for a company that provides dependable equipment and strong technical support. A good distributor should understand the needs of your industry and help match your shop with the right machines. It’s also important to evaluate their training options, service availability, and long-term parts coverage. Working with an experienced distributor ensures you have guidance before, during, and after installation, helping your team use the equipment confidently.