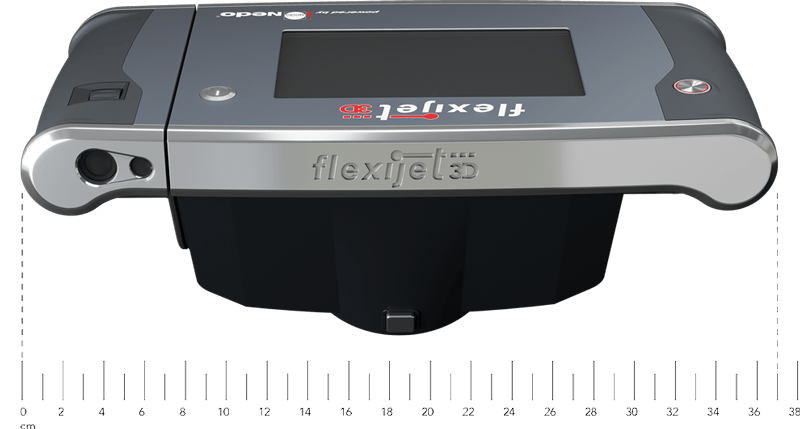

FLEXIJET 3D LASER MEASURING SYSTEM FOR PRECISION

Red Dot Design Award Winner

Thousands of Professionals Using Flexijet Worldwide

Dealing with complex measuring tasks on-site? Tired of fumbling with tape measures or templates? The Flexijet 3D laser measuring system provides flexibility and mobility for CAD-ready files with high precision.

What Makes the Flexijet 3D Unique?

The Flexijet 3D is an innovative mobile and flexible measuring system designed to transform how you approach measurement tasks. Here are some of its standout features:

- Precision Accuracy: Achieve 3D laser measurements down to the millimeter for all your CAD measurement needs, reducing rework and inaccurate measurements.

- CAD-Ready Files: Instantly create files compatible with CAD software, streamlining your workflow and reducing the need for manual data entry. It also supports DWG, point clouds, and CAD data exports through a variety of export interfaces, making it easy to work across different platforms.

- User-Friendly Interface: The intuitive design allows users of all skill levels to operate the system efficiently, minimizing the learning curve. The Flexijet Face display and Flexijet Smart Remote App enable seamless control during fieldwork, even for high-up or awkward angles.

- Versatile Applications: Ideal for many industries, including construction, interior design, and manufacturing, the Flexijet 3D adapts to

your specific needs. Recognized with a Red Dot Design Award, it combines innovation with

real-world functionality for professionals requiring digital measuring and fast field-to-CAD transfer. Whether you're managing a construction site or a custom build, this measuring device transforms how you plan and document spaces.

Use Cases of Our Flexijet 3D Measurement System

The Flexijet 3D laser measuring system has a wide range of applications across various industries. Some of the key use cases include:

- Kitchen and Interior Design

- Architecture and Surveying

- Glass and Storefront Construction

- Furniture Making and Carpentry

- Stonework and Masonry

- Metalwork and Staircase Construction

These industries benefit from Flexijet 3D automatically measures capabilities, saving time and labor on measurements of building interiors, staircases, and on-site assembly tasks. The system is designed for complex measurements, offering complete flexibility as Flexijet 3d can be reoriented at any time without recalibrating.

Who Can Use Our Flexijet 3D Measurement System?

Users can be found in many different sectors of planning, trade, series manufacturing, and industries:

- Kitchen work

- Store, object, and interior work

- Architects and surveyors

- Glass and storefront construction

- Furniture makers and carpenters

- Stoneworkers/masons

- Metalwork

- Staircase construction

- Evaluators

- Booth/exhibition construction

- And many more…

Whether you're preparing CAD points during planning or finalizing drilling and mounting, the Flexijet measuring device provides flexible options for collecting accurate data. Users can capture points through free measurement or predefined layouts, including elements such as walls or irregular surfaces. The system connects workflows from Flexicad software to any compatible computer-aided platform and supports both high-volume and custom applications.

Simple, Easy-to-Use Process of the Flexijet Templating System

Using the Flexijet 3D Measurement System is straightforward and user-friendly. Follow these steps to get started:

- Choose the Ideal Location: Identify the best spot in the room for measurement.

- Power On: Turn on the device; there's no need to align the stand.

- Select Marking Points: Choose from a variety of marking options in the CAD software, such as Line, Curve, or Spline.

- Position the Laser: Move the laser to the target point, either manually or using the remote control.

- Start the Measurement: Initiate the measurement by tapping the touch sensor or using the remote controller.

- Generate 3D CAD Drawing: A detailed 3-dimensional CAD drawing will be created automatically.

Note: A notebook, PC, or tablet is not included with the delivery.

Work smarter, not harder, with

Diversified Equipment and Supply and join the thousands of satisfied users who have transformed their workflow with the

Flexijet 3D laser measuring system!

WANT TO LEARN MORE ABOUT THE FLEXIJET 3D?

This is just another way Diversified Equipment and Supply can help you grow your business more profitably. Try our Flexijet 3D Laser today and discover the Diversified difference.

The Flexijet 3D is used across many industries, including kitchen work, interior projects, architecture, surveying, furniture production, stonework, metalwork, and custom fabrication. Its flexibility allows teams to gather accurate digital measurements for both small and complex jobs.

Whether you handle storefront construction, staircase work, exhibition builds, or ship interiors, the system supports reliable field-to-CAD workflows. If you would like guidance on whether the FLEXIJET 3D LASER, the Flexijet 3D measurement system, or Flexijet templating fits your environment, our team is available to talk through your needs.

This is just another way Diversified Equipment and Supply can help you grow your business more profitably.

Try our Flexijet 3D Laser today and discover the Diversified difference!

CONTACT US WITH QUESTIONS OR TO PLACE AN ORDER.

Call: (704) 545-5198

Email: info@descncrocks.com

Frequently Asked Questions About the Flexijet 3D Laser

What is the FLEXIJET 3D LASER used for?

The FLEXIJET 3D LASER is used to capture accurate digital measurements on-site and transfer them directly into CAD software for planning and documentation. It helps users measure rooms, structures, and project elements without relying on manual tools. The system records precise points, lines, and surfaces, making it useful for interior design, construction, millwork, and fabrication work where dependable measurement data is required for creating clear and consistent project layouts.

Is this a full Flexijet 3D measurement system?

Yes, this is a complete Flexijet 3D measurement system designed to support industries such as construction, interior design, architecture, and surveying. It includes the hardware and software needed to gather accurate on-site measurements and generate CAD-ready information. With Flexicad integration, users can record details, capture complex shapes, and produce drawings efficiently. The system works for both simple and challenging spaces, making it dependable for daily measurement and layout tasks.

Does Flexijet templating reduce measurement errors?

Yes. Flexijet templating reduces measurement errors by capturing digital points directly into CAD rather than relying on manual methods. This helps prevent misalignment, incorrect angles, and inconsistent dimensions during fabrication or installation. Because the laser records accurate positions, teams can reference reliable data throughout the project. This process supports clearer communication, smoother planning, and more dependable results, especially when working with detailed or irregular project layouts.

Who typically uses the Flexijet 3D Measurement System?

The Flexijet 3D laser system is used across many industries, including kitchen work, interior and store fitting, architecture, surveying, glass and storefront construction, furniture making, stonework, metalwork, staircase construction, exhibition building, and ship interior projects. It is designed to support both small custom jobs and larger production workflows that require accurate digital measurement. If you’d like to determine whether Flexijet suits your specific work environment, please contact us, and we’ll guide you through the options.