Used Lumber Optimization System for Dimensional Lumber

Description

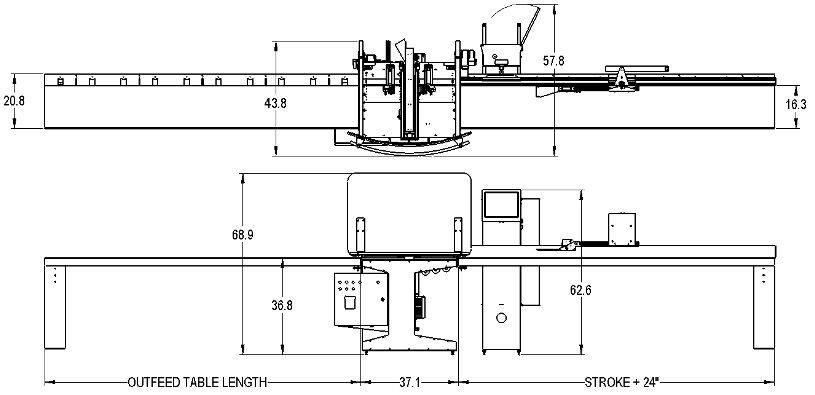

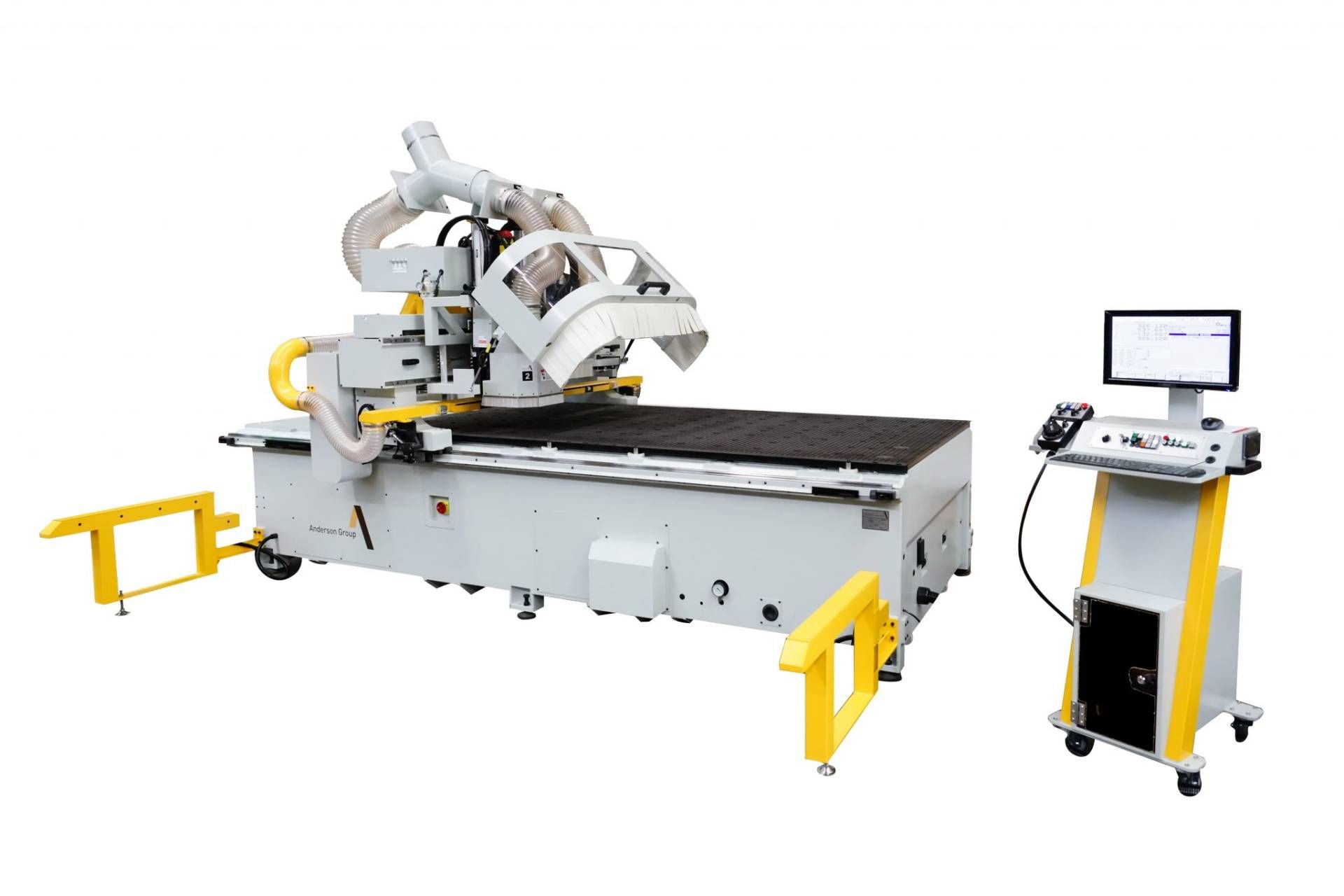

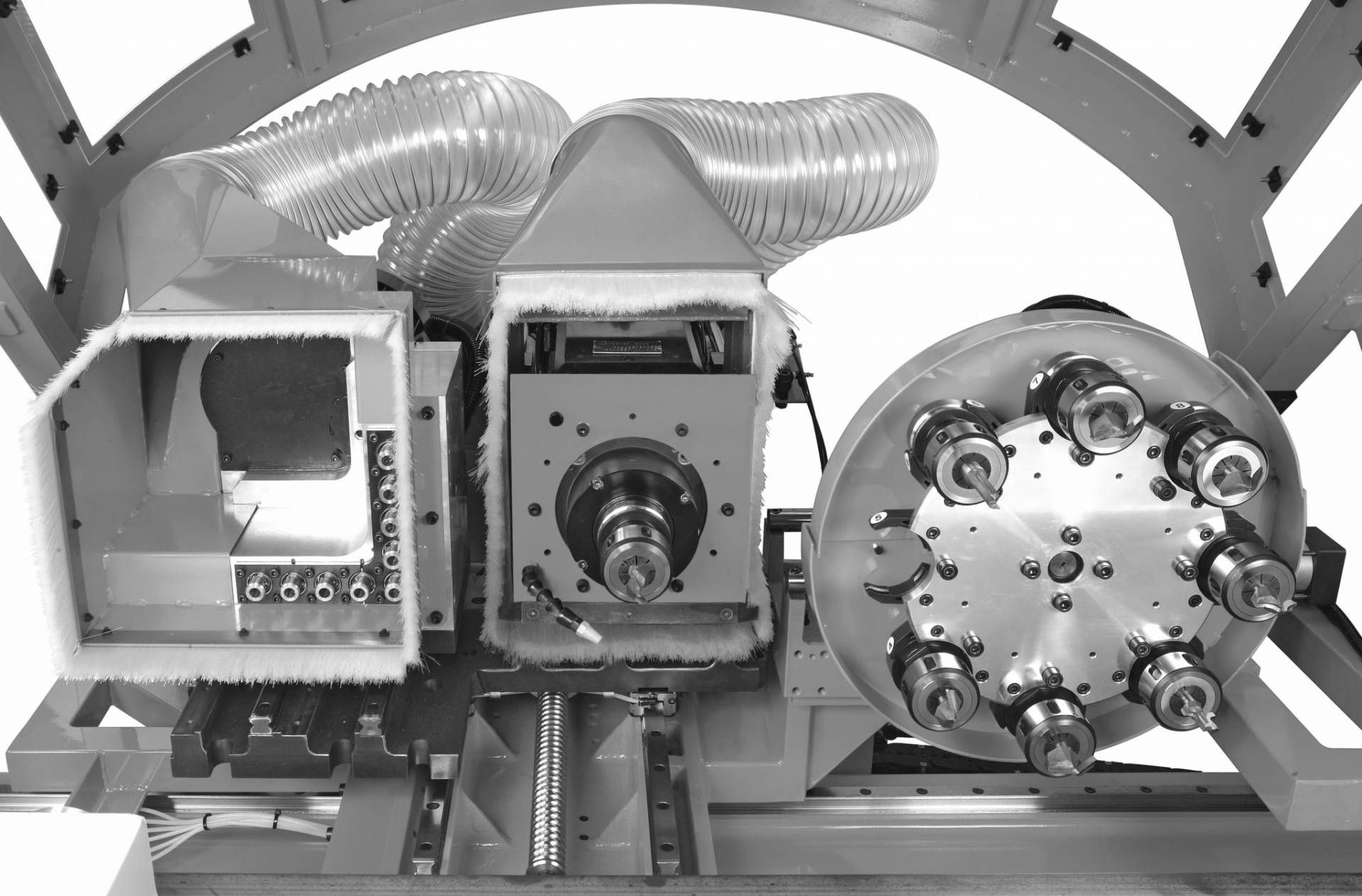

The Ultimizer automated system was used to scan lumber, identify defects, and remove them prior to further processing into survey stakes and wood components. By eliminating defects early, the system helped improve yield, consistency, and finished product quality.

This machine has been maintained by Diversified Equipment and Supply (DES) and is well suited for manufacturers producing stakes, strips, or other value-added wood products.

Common Applications

- Defect detection prior to stake production

- Lumber optimization and cut-off processing

- Yield improvement for linear wood products

Key Benefits

- Automated scanning and defect removal

- Improves usable material recovery

- Reduces manual inspection

- Supports continuous production flow

Condition

- Used

- Maintained by DES

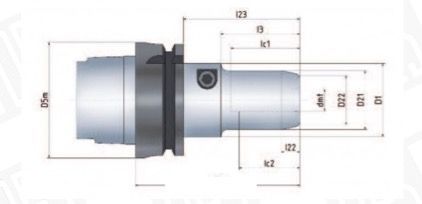

- Configuration details available upon request